The Critical Role of Climatic Chamber in Modern Industry

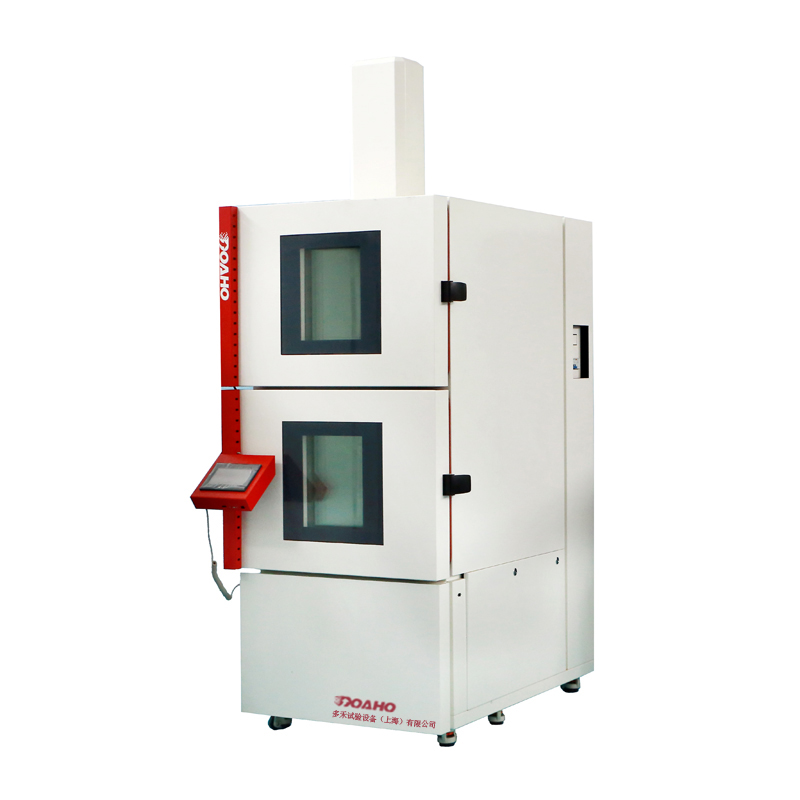

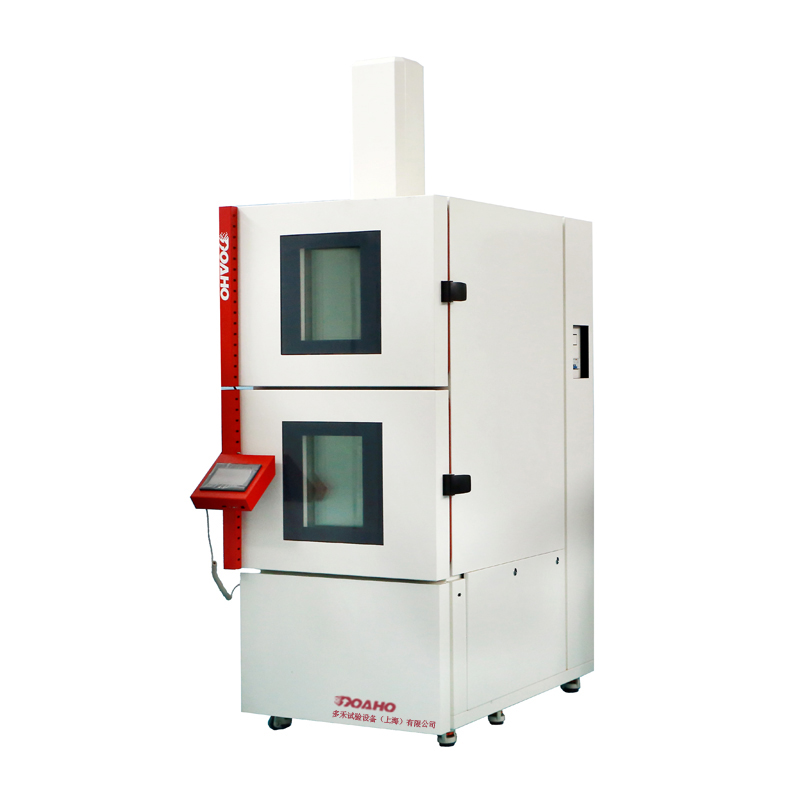

In an era where products must endure extreme environments – from scorching deserts to freezing tundras – climatic chambers have emerged as indispensable tools for ensuring quality, safety, and compliance. These advanced systems simulate precise temperature, humidity, and atmospheric conditions to test the durability of materials, electronics, automotive components, and pharmaceuticals. As industries face stricter regulations and consumer demands for reliability, manufacturers like Doaho Test Equipment Co., Ltd. are pioneering innovative climatic test chamber solutions that redefine resilience testing.

Core Features of Advanced Climatic Testing Chamber

1. Precision Environmental Control

– Temperature Range: From -80°C to +180°C, supporting rapid thermal cycling (e.g., 15°C/minute) for accelerated aging tests.

– Humidity Accuracy: 10% to 98% RH with ±1% stability, critical for testing moisture-sensitive electronics or pharmaceuticals.

– Atmospheric Simulation: Adjust oxygen, CO2, or corrosive gas levels for specialized aerospace or marine applications.

2. Smart Automation & Data Integrity

– AI-Powered Predictive Maintenance: Algorithms monitor compressor health and humidity generators, reducing downtime by 30%.

– 21 CFR Part 11 Compliance: Secure, auditable data logging for pharmaceutical and medical device trials.

3. Modular Design for Scalability

– Benchtop to Walk-In Chambers: Compact 100L units for R&D labs vs. 50m³ walk-in chambers for full-scale automotive testing.

– Explosion-Proof Options: Safely test lithium-ion batteries or volatile chemicals under extreme conditions.

Industry Applications of Climatic Test Chamber

1. Automotive & Electric Vehicles (EVs)

– Battery Stress Testing: Validate Li-ion packs under -40°C to +85°C cycles to meet UN 38.3 safety standards.

– Component Durability: Test rubber seals, infotainment systems, and sensors in simulated Saharan heat or Arctic cold.

2. Electronics & Consumer Tech

– Smartphone Reliability: Expose devices to 95% humidity and 55°C to assess screen delamination or circuit corrosion.

– IoT Device Validation: Ensure agricultural sensors function in -30°C frost or tropical monsoon conditions.

3. Aerospace & Defense

– Altitude Simulation: Replicate 30,000-foot conditions to test avionics cooling and cabin pressure systems.

– Material Fatigue Analysis: Expose turbine blades to cyclic thermal shocks from -65°C to +120°C.

4. Pharmaceuticals & Biotechnology

– Vaccine Stability Studies: Monitor degradation under ICH Q1A-guided conditions (25°C/60% RH or 40°C/75% RH).

– Biocompatibility Testing: Validate surgical implants in body-temperature saline environments.

Choosing a Climatic Chamber: 5 Essential Factors

1. Test Standards Alignment: Verify compatibility with MIL-STD-810 (military), ISO 16750 (automotive), or ASTM D4169 (packaging).

2. Chamber Size & Flexibility: Opt for modular designs that adapt to evolving product dimensions.

3. Energy Efficiency: Prioritize chambers with ENERGY STAR® ratings or heat pump technology.

4. After-Sales Support: Ensure access to 24/7 technical assistance and spare parts inventory.

5. Data Security: Select systems with encrypted cloud storage for sensitive defense or medical data.

Future Trends in Climatic Testing Technology

1. AI-Driven Failure Prediction

Machine learning models will analyze real-time chamber data to forecast material defects before physical failure occurs.

2. Hybrid Stress Testing

Combine climatic conditions with vibration, UV exposure, or salt spray for multi-factor durability validation.

3. Green Testing Solutions

– Solar-Powered Chambers: Off-grid testing units for remote mining or Arctic research stations.

– Waterless Humidity Control: Adsorption-based systems that cut water usage by 90%.

Case Study: Accelerating EV Innovation with DHT

A European EV startup reduced battery certification time by 22% using Doaho’s WCT-9800 Extreme Climate Chamber. The chamber’s rapid cycling (-40°C to +85°C in 8 minutes) enabled 500 thermal shock cycles in 10 days, securing UN ECE R100 certification ahead of schedule.

DHT: Leading Innovation in Climatic Testing Chambers

As a trailblazer in environmental simulation technology, Doaho has delivered cutting-edge climatic testing chamber solutions to over 50 countries. Their clients include global giants like Tesla, Siemens, and Novartis.

Key Advantages of DHT’s Climatic Chambers

1. Proprietary Technology

– Dynamic Humidity Control (DHC™): Achieves 98% RH in <10 minutes, outperforming industry averages by 40%.

– Multi-Zone Testing: Simultaneously simulate different climates (e.g., tropical heat and desert dryness) in one chamber.

2. Sustainability-Driven Design

– Energy Recovery Systems: Reuse 80% of waste heat from refrigeration units, slashing power consumption.

– Eco-Friendly Refrigerants: R-290 and R-513A options reduce global warming potential (GWP) by 75%.

3. Custom Solutions for Niche Markets

– Solar Panel Testing: Chambers with 1,500 W/m² solar radiation simulation for renewable energy R&D.

– Food Safety Compliance: Corrosion-resistant stainless steel chambers for USDA and FDA food storage trials.

4. Global Certifications

– ISO 17025 Calibration: Ensures ±0.3°C temperature uniformity across all test zones.

– CE, UL, and RoHS Compliance: Meets EU, North American, and Asian regulatory requirements.

Conclusion: Partnering with DHT for Unmatched Reliability

Climatic test chamber is the backbone of product validation in a world where resilience is non-negotiable. By collaborating with innovators like Doaho Test Equipment, industries gain access to precision-engineered climatic test chamber solutions that ensure compliance, reduce time-to-market, and build consumer trust. Elevate Your Testing Standards: Visit https://doahotest.com/ to explore technical specifications, client testimonials, and customized climatic chamber solutions tailored to your industry’s needs.

Leave a comment